Contact Us

Contact: Mr.Zhu

Mobile:86 139 2156 0022

Phone:86 511 88395500

Company Fax: 86 511 88391300

Company Email: yztfl@163.com

|

|

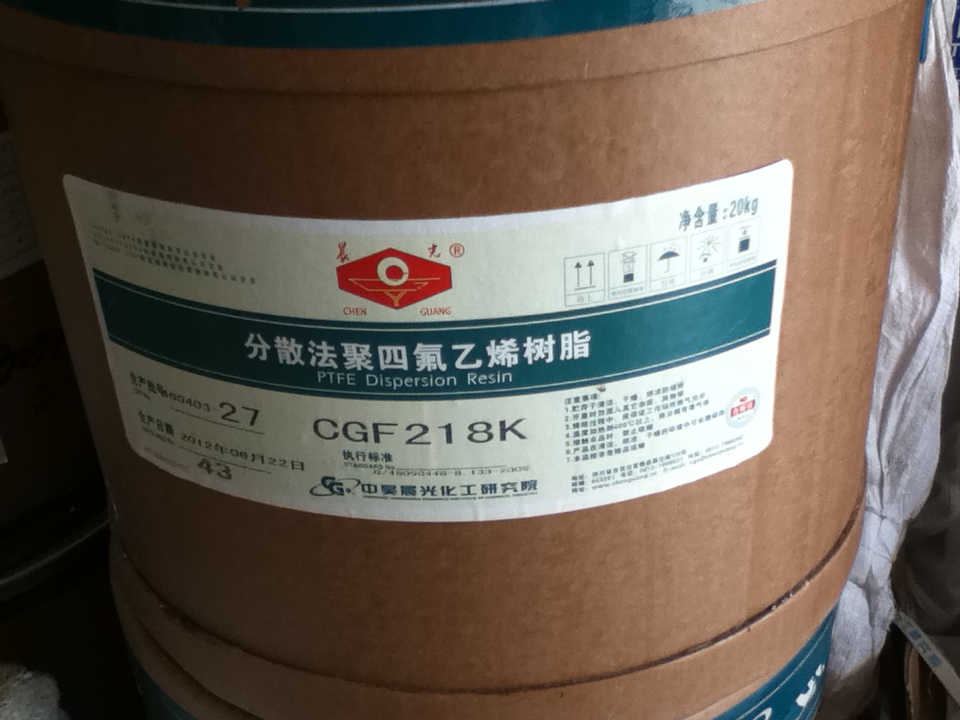

PTFE Powder CGF-218

Productname:PTFE Powder CGF-218

Details

PTFE Powder CGF-218

(for making seal tapes by paste extrusion)Molecular Formula: [CF2--CF2]n

CAS No. 9002-84-0

Description :

In addtion to all excellent properties of PTFE material, CGF-218 series powders has outstanding performance in paste extrusion to manufacture sealing tape, etc.. The resin are processed by mixing them with some organic solvents to obtain paste which are made into coherent, smooth and flat semifinished products after ram extrusion. Druing this progression the extruding pressure remains steady .The semifinished products can be further processed to produce unsintered tape by calendering, enlongating and removing solvent with heat, and also to manufacture sintered coherent thin-walled tubing , continuous long rod, and wire & cable coating, etc..

Typical properties :

GRADE

CGF-218H

CGF-218K

Bulk Density

420 +/- 100 g/l

Average Particles Size

750+/- 150 um

Moisture content

max. 0.04%

Specific Gravity

2.19 - 2.25

Melting Point

327 degree C

Tensile Strength

24 MPa

23 MPa

Elongation at break

350 %

300%

Heat Instability Index

30

50

Main Applications

Oil-free unsintered broad tape for cutting apart

Tape width

250mm or more available

Extrusion pressure

20 +/- 5 MPa

Extrudate appearance

flat, smooth and coherent

Comparison of the typical physical properties of the tapes (streching ratio: 24:1, tape thickness 0.03 - 0.08 mm)

Seal tape properties

CGF-218H

CGF-218K

Whiteness

Better

Good

Clarity

opaque

Slightly transparent

Tensile Strength

15 MPa

12 MPa

Elongation at break

30 %

25%

Typical processing conditions for making seal tape:

1. Liquid Extrusion Aid: Aero Kerosene

2. Mixing ratio of the PTFE powder to the liquid extrusion aid: 100 g : 20.3 ~ 20.4 g .

3. Temp. and time for extrusion aid infiltration before extrusion : 8 ~ 10 hr. at 45 ~ 55 OC

4. Ram extrusion temp.: 50OC ~ 60 OC

5. Calendering temp. : 60 + - 10 OC

6. Oil removing temp. (for drying) : 200 + - 10 OC

7. Elongating temp. : 285 + - 15 OC

8. Tape thickness : 0.060 + - 0.005 mm

Packaging, storage and transportation

20kg net packed in double PE plastic bags with a cardboard drum outside.

Store in clean, cool ( preferably 5-20 degree C) and dry place

Open containers and use the material in clean environment only.

Related News |

English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Russian

Russian